Blog

How Thick Are The Walls In A Typical Tiny House?

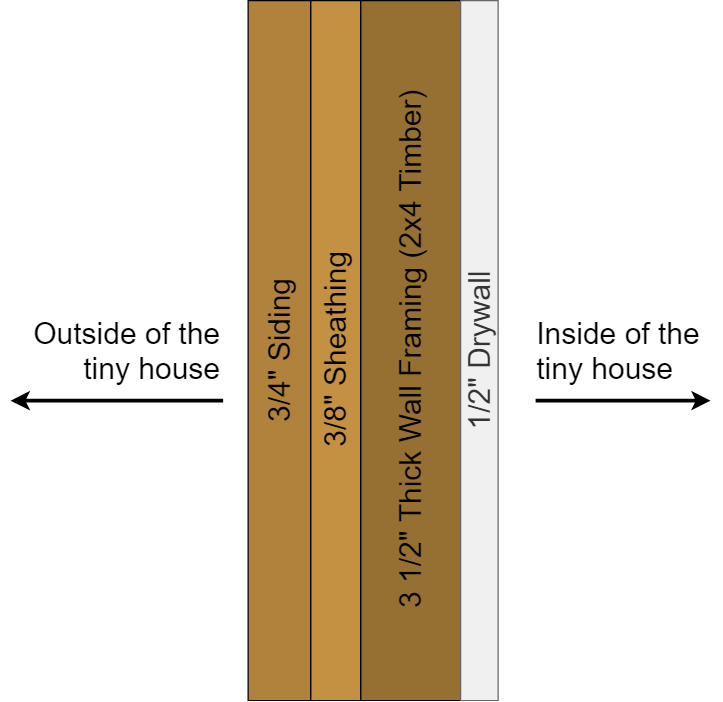

When building a tiny home which is no bigger than 400 square foot (37 square meters), space is obviously at a premium. However for simple (permit free) movement of a tiny house on wheels on the roads, many people stick to the ‘8.5 by 40’ rule: i.e. no more than 8.5 foot wide and 40 foot long. This leads to a floor space of 320 square foot (30 square meters) or less. When you really think about this, 8.5 foot is not all that much: only a foot or so more than some NBA players! So the thickness of the walls is really important. If you go with thick timbers (to accommodate thick insulation), you might find that your external walls are almost 7” (18 cm): meaning 14”+ overall for both sides, which is almost 14% of your 8.5-foot width! So you really need to think about wall thickness in a tiny house.

In general, when using standard 2×4 inch wood, external walls will be a little over 5” thick (or more if you use fairly bulky exterior siding) and interior walls will have a thickness of around 4½” (due to the drywall on both sides).

This article explores this in more detail below, including how to represent it accurately on a floor plan, as well as whether you can reduce the thickness of your walls to eke out every bit of extra usable space!

Typical External Wall Thickness

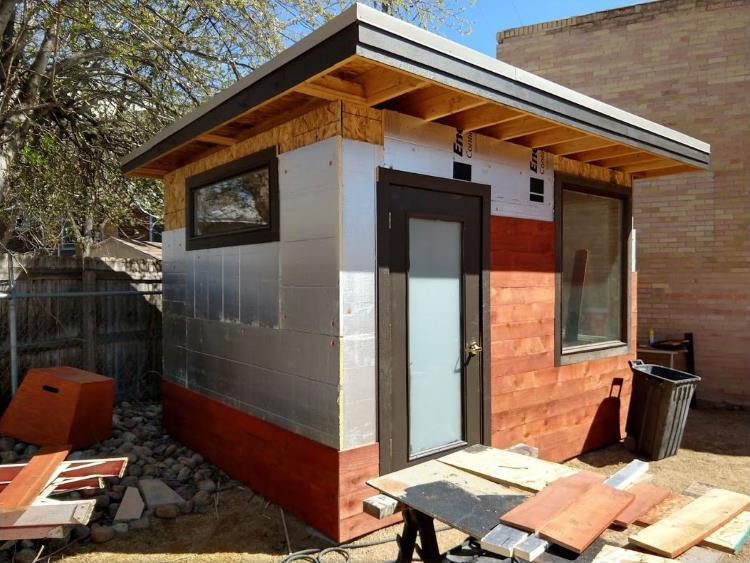

A typical external wall will naturally be timber framed, with drywall attached to the inside. The outside will have OSB or plywood sheathing attached to the frame, and then an exterior siding (cladding) to make the exterior of your tiny house look nice. In other words, it will look as follows:

The above leaves off very thin materials like housewrap, vapor barriers and bitumen-based flashing tape because they only have a negligible impact on width. So to sum up the thickness:

- ½”: drywall to the interior, which is then decorated as needed.

- 3½”: 2×4” wood for the timber frame, which is not 4” but 3½” after milling.

- ⅜”: typical thickness of exterior sheathing, which attaches to the outside of the timber frame (and helps improve the stability of the frame, along with giving the siding something to stick to).

- ¾”: exterior siding (also called cladding). This can be a range of materials, including thin metal, but a typical wooden siding plank is around ¾” thick.

- 5⅛”: total (13cm), with our ‘math hat’ on!

This might not seem like a lot, although it will add up to 10% of the overall width of a 8.5 foot wide tiny house on wheels. Plus some people in colder climates might use thicker wall frame timber and may also add 1” foam insulation board to the outside (before the siding): adding up to 15% (or more) of the overall width. We explore possibilities for thinner walls in a future section, but before we do that we wanted to explore some of the different thickness materials you can use.

The thickness of the wood you use for the timber frame will naturally dictate how much insulation you can fit between it. Standard 2×4” timber will limit you to 3½” (or thinner) insulation material, which tends to offer R-13 or R-15 of insulation. However by using 2×6” wood (offering 5½” thickness), the thicker insulation you use will typically offer R-20 or R-21 protection.

This will naturally add 2” to each wall and so 4” overall, bumping up the overall ‘use’ of your 8.5 foot (102”) tiny home width from 10% to 14%. It is naturally a judgement call as to whether you need the extra width for insulation.

Next up, you can naturally get ⅜” or ⅝” drywall instead of the more standard ½”. Typically the thickness of drywall does not make much difference at all (especially to exterior walls where the drywall is only on one side of the wall frame), but it is worth mentioning that different thicknesses are available.

We mentioned about using ¾” siding for standard wooden planks, although this is an area you can cut down on. Since the siding is decorative and not really structural/insulative, have a look at other siding options. You can use thin sheets of metal which could be as thin as ⅛”, whilst corrugated metal might actually take up more thickness than expected due to its ‘wavy’ pattern.

Finally, some people use 1” of foam insulation board outside the exterior wall, between the sheathing and siding:

This again depends on how cold or warm your climate is, but an extra 2” overall (on both sides) will also have a noticeable impact on your wall thickness.

Now that we have covered different material thickness, possibly the thickest wall you will find on a tiny house (made for a colder climate) will be:

- ⅝”: drywall.

- 5½”: 2×6” wood for the timber frame.

- ⅜”: typical thickness of exterior sheathing, which attaches to the outside of the timber frame (and helps improve the stability of the frame, along with giving the siding something to stick to).

- 1”: foam insulation board.

- 1”: exterior siding.

- 8½”: total (21½ cm).

17” thick walls on both sides will be 16.7% of the overall width (for a 8.5 foot tiny house on wheels).

Alternatively, the thinnest wall you can probably get (using standard materials and construction techniques) will be:

- ⅜”: drywall.

- 3½”: 2×4” wood for the timber frame.

- ⅜”: typical thickness of exterior sheathing, which attaches to the outside of the timber frame (and helps improve the stability of the frame, along with giving the siding something to stick to).

- ⅛”: exterior siding.

- 4⅜”: total (11 cm).

This is a lot thinner, with less than 9” of wall thickness on both sides being just 8.8% of the overall width of our 8.5 foot house.

Typical Internal Wall Thickness

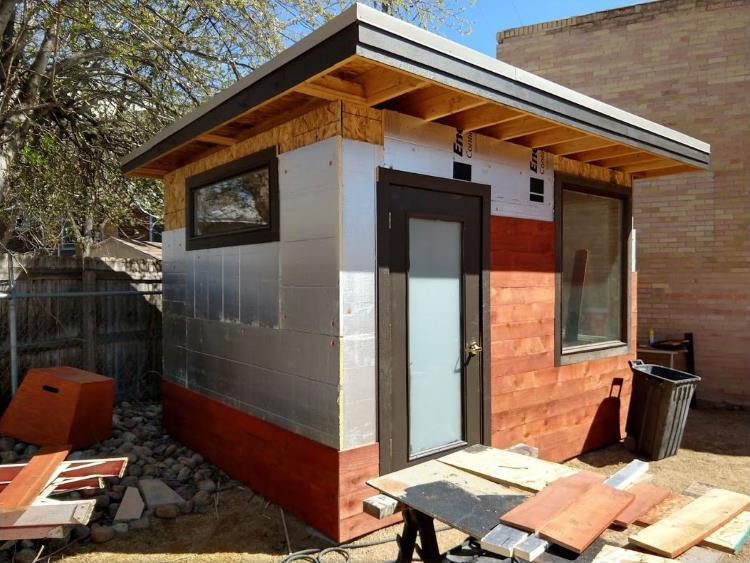

A standard interior wall will also be timber framed, with drywall on both sides of the wall. Then both sides will be decorated as needed. A diagram showing the rough idea (minus any decoration or protective sheeting) is:

So a standard internal wall will have the following thickness:

- ½”: drywall for room 1.

- 3½”: 2×4” wood for the timber frame, which is not 4” but 3½” after milling.

- ½”: drywall for room 2.

- 4½”: total (11.4cm).

This is very standard, although as we explored above, drywall can also typically be bought in ⅜” or ⅝” thicknesses – granted, this will have a very small overall impact to wall thickness (no more than ¼”).

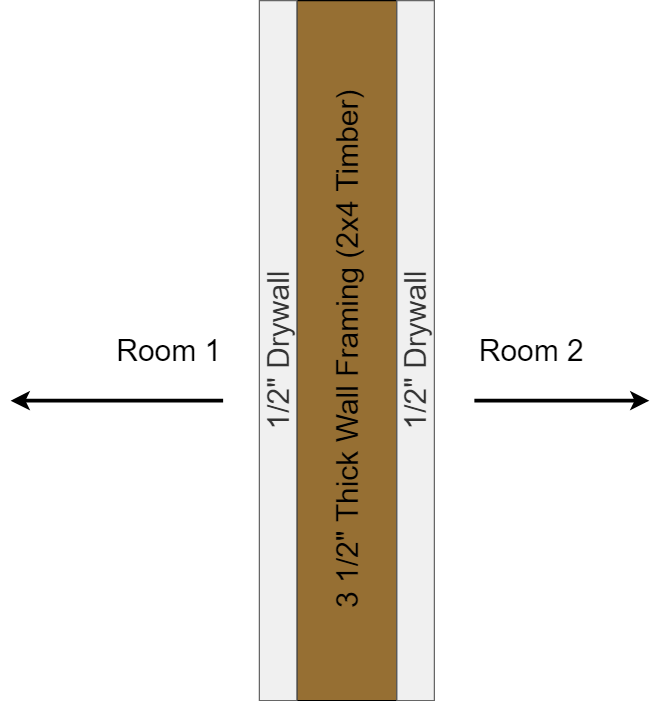

The main variation to a standard 4½” internal wall is if you wanted to aim for extra sound or thermal insulation, either by using specialized soundproof or thermally-designed drywall, or by including an air barrier/gap in the internal wall construction. Some specialized drywall is still only around ½” thick, although some can be thicker than normal (1-1½”). Plus an air gap will probably be at least 1” (3cm) too.

So aiming for extra sound/thermal insulation could see the overall internal wall being 5½” (14cm) thick instead.

Representing Wall Thickness In Floor Plans

When designing your tiny house, make sure that you include the wall thickness on your detailed plans. As we have seen above, the exterior walls can take up 9-17% of your tiny home’s width so it is imperative that your detailed plans take this into account.

You should find that most paid-for floor planning software includes the option for it (because wall thickness will matter to builders even if a mansion is being built!), although some free versions of floor plans do not always include the option for it – especially if they are designed to give a quick 2D representation of your house. Thankfully, both RoomSketcher and HomeStyler (two of the main floor planner options) include the option to vary the wall thickness. You can find our overview of the best free and premium designing software for tiny houses here.

Can You Get Thinner Walls?

The walls that we have mentioned previously are mainly load-bearing walls, even though non-load bearing walls tend to be 4½” thick for consistency too. However some internal walls can be as little as 2½” thick (depending on your local building codes) and these are known as ‘narrow walls’ which are not load bearing.

Narrow walls are most commonly used for things like cupboards, closets and separating master bedrooms with the dedicated bath/toilet room (sometimes called an en-suite), and they are made by using 2×4” wood but turning it the other way so that the 2” (1½” after milling) thick edge is used to provide the width. Then ½” drywall is applied to both sides, leading to a 2½” narrow wall. Sometimes 2×2” wood is used instead of 2×4” wood, however.

It is worth noting that these cannot be used for your exterior walls: not only would your tiny house be cold (due to allowing just 1½” of insulation), but they would not be stable enough (in that they would not adequately support the load of the ceiling timbers).

There might also be local building code restrictions, such as not being able to use narrow walls between bedrooms (for a few reasons, including that their sound insulation would not be great). Some local planning offices might noy allow narrow wall use at all, either, so be sure to double check the exact rules before using them and saving yourself a valuable 2”.

How Wall Thickness Can Affect Roadworthiness

We mentioned at the start of this article that a standard tiny house on wheels (i.e. on a trailer) can usually be transported on highways without a special permit if it adheres to the ‘8.5 x 40’ rule (i.e. not being more than 8.5 foot wide). However this can vary state-by-state, so do not take the ‘8.5 x 40’ rule as gospel!

If you decide that 8.5 foot wide will not be enough for what you are planning on building, you can naturally build beyond this: it just means that you will need to obtain a special ‘wide load permit’ when transporting your THOW.

This can average around $65 per state, so it is not a massive amount even if you cross a few state lines (which would require you paying in each state: i.e. $260 if you go through four states in total). You can find more information on the max size and weigth for a tiny house on wheels without permit here. There are other considerations to building beyond 8.5 foot, however, as TinyHouseBuild explores in their handy guide.